What Are You Looking For?

A Comprehensive Revelation of the Structure, Performance and Packaging Details of Pouch Cells

Jun 10, 2025

1.Introduction and Prospects of Pouch Cell

Pouch cells are essentially cells that use aluminum plastic film as the packaging material. Generally speaking, the packaging of lithium-ion batteries can be divided into two categories: soft-pack cells and metal-shell cells. Metal-shell cells include steel shells and aluminum shells, as well as cylindrical and square types.

Polymer batteries stand out among various battery types due to their special packaging materials and structural design. From a safety perspective, the packaging of aluminum plastic film provides natural safety guarantees. When safety hazards occur, pouch cells tend to release pressure in a gentle way by bulging and cracking, which contrasts sharply with the explosion risks that steel shells and aluminum shells batteries may cause. In terms of weight, soft-pack batteries have excellent lightweight characteristics. Compared to steel-shell lithium-ion batteries of the same capacity, their weight can be reduced by 40%; compared to aluminum-shell lithium-ion batteries, they can achieve a 20% weight reduction. This makes them highly competitive in applications where weight is a critical factor.

In terms of electrical performance, the internal resistance of pouch cells is significantly lower than that of ordinary lithium-ion batteries. This low internal resistance characteristic effectively reduces battery self-discharge and helps improve energy utilization efficiency. In terms of cycle life performance, pouch cells are also commendable. After 100 cycles, the battery's capacity degradation is 4%-7% less than that of aluminum-shell batteries, meaning it can provide more durable and stable power support. Moreover, pouch cells have extremely high flexibility in design. They break through the shape limitations of traditional batteries and can be customized to any shape, even achieving extreme thinness, meeting the diverse needs of customers for different cell models, providing more possibilities for product innovation.

Soft-pack accounts for more than 50% of the market share in the field of power batteries. According to statistics, in 2023, the global market share of soft-pack power batteries reached 42%, an increase of 6 percentage points. In the energy storage field, pouch cells, with their flexible design and high cycle life characteristics, have seen an increase in installed capacity in distributed energy storage projects by over 50% year-on-year.

Continuous technological breakthroughs also support the rise of pouch cells. By optimizing the aluminum plastic film packaging process, the energy density of batteries has increased to above 300Wh/kg, approaching the level of solid-state batteries; the mature application of lamination technology has increased production efficiency by 30% and reduced manufacturing costs by 15%. With the mass production of sodium-ion pouch cells in 2024, their advantages in low-temperature performance and cost control are expected to drive the market share of pouch cells in specialized markets such as electric two-wheelers and low-speed electric vehicles to reach new heights, further consolidating their leading position in the field of power batteries.

2.Production details

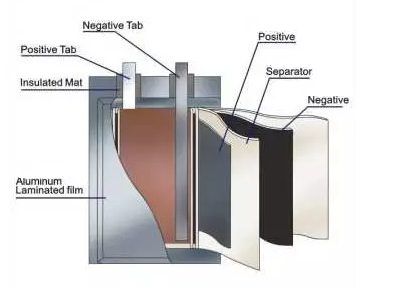

Compared with steel-shell lithium batteries of the same size specification, the capacity of ternary pouch batteries is 10-15% higher; compared with aluminum-shell batteries, the capacity can also be increased by 5-10%. Moreover, under the same capacity specification, pouch batteries are lighter in weight. This "high capacity and lightweight" characteristic gives them a significant advantage in the new subsidy policy. Industry experts predict that with the development and evolution of battery technology routes, the penetration rate of pouch batteries in the new energy vehicle market will continue to rise, and the proportion of various types of batteries is expected to exceed 50% in the future. The difference in battery shell materials determines the different packaging methods. Pouch batteries use aluminum plastic film as the shell and adopt a heat packaging process; while metal-shell batteries usually use laser welding to seal. The aluminum plastic film is composed of three layers, each layer has a clear division of labor and works together to protect the cell. The outermost nylon layer not only gives the aluminum plastic film a stable shape, reduces damage to the battery shell from the outside, but also effectively blocks the penetration of air, especially oxygen, maintaining the stability of the cell internal environment and ensuring the good flexibility of the packaging aluminum foil.

The middle A layer is made of metal aluminum, which acts like a solid waterproof barrier, preventing water and moisture from penetrating into the cell interior. It should be noted that lithium-ion batteries are extremely sensitive to moisture, and the moisture content of the electrode sheet is usually required to be at the PPM level. The presence of the AI layer is crucial. In addition, the A layer also provides plasticity during the formation of the aluminum plastic film, facilitating the processing of punch holes. The PP (polypropylene) layer in the innermost layer is the core of the heat packaging. At 100 degrees Celsius, the PP layer melts and becomes viscous, through the heating of the sealing head to melt and bond it, and after cooling, it achieves a firm packaging. Moreover, the PP layer will not be dissolved or swollen by the organic solvents in the cell, effectively isolating the internal electrolyte from the AI layer and preventing the AI layer from being corroded, ensuring the safe operation of the battery.

The aluminum plastic film may seem simple in structure, but in the production process, achieving the uniform and firm composite of the three materials is a major technical challenge.

In the production process of pouch batteries, one process is similar to that of conventional battery manufacturing, and this will not be elaborated in detail. The forming process of the electrode sheet and the electrode lead is unique: the electrode sheet is usually precisely formed by die-cutting, while the electrode lead can be processed by laser cutting or die-cutting. The stacking of electrode sheets is the key step in pouch battery production. Common stacking methods include Z-shaped electrode sheet stacking and winding-type electrode sheet stacking, where the cut electrode sheets are stacked one by one, fixed by adhesive tape to form a coil core, and then placed in the formed aluminum plastic film groove. The pouch cell has the advantage of local customization, which can be designed with different size specifications according to customer requirements. After determining the shape dimensions, a special mold needs to be customized to complete the aluminum plastic film forming process, which is commonly known as "punching holes". This process is carried out under heating conditions, using the forming mold to punch out the groove that matches the coil core on the aluminum plastic film, providing a precise accommodating space for the subsequent cell assembly and ensuring the overall structure and performance of the pouch battery.

After the aluminum plastic film is formed by punching and cutting, it is called a Pocket bag. In actual production, the punching form of the Pocket bag needs to be flexibly selected according to the thickness of the cell: when the cell is thin, usually single-pit punching is used; if the cell is thick, double-pit punching is selected. This is because the deformation capacity of the aluminum plastic film has an upper limit. If forced excessive stretching and punching, it is very likely to cause material rupture, affecting the safety and integrity of the battery.

Furthermore, during the production process, stamping operations will be carried out in the airbag area based on the requirements, and air structures will be added. These air components play a crucial role during the battery formation stage, as they can effectively collect the gases generated during the formation process, preventing the accumulation of gases from affecting the performance and structure of the cell, and ensuring the stability and reliability of the pouch battery in the subsequent usage process.

Place the folded coil core into the formed pit.

The coil core is placed into the pit, and after several processing steps, the area that needs to be encapsulated is required.

After precisely placing the coil core into the aluminum-plastic film forming cavity, the entire aluminum-plastic film needs to be inserted into the fixture and moved to the top-side sealing machine for top sealing and side sealing operations. During the packaging process, the two sealing heads need to be preheated to a specific temperature (usually around 180℃). When the sealing heads close and apply pressure on the aluminum-plastic film, the inner PP (polypropylene) layer is heated and melts, achieving a firm adhesion of the aluminum-plastic film through adhesiveness.

Details of the top sealing process: The core of the top sealing process is the sealing of the tab area. This process relies on the key component on the tabs - tab glue. The tab glue has the characteristic of thermal fusion and adhesion. The PP material inside the tab glue and the PP layer of the aluminum-plastic film melt simultaneously under heating conditions, forming an integrated sealing structure. This process not only ensures that the tabs are isolated from the outside world, avoiding short-circuit risks, but also enhances the packaging strength and air tightness through molecular-level bonding between the materials, providing a guarantee for the safety performance of the pouch battery.

After the pouch cells are completed with top sealing and side sealing, they need to undergo X-ray inspection to check the alignment of the coil core, ensuring the internal structure is accurate and error-free. Once the inspection is passed, the battery cells enter the drying room for the dehydration process. They are left to stand in the drying environment for a specific period of time to remove the water vapor from the aluminum-plastic film and the internal residues, to prevent any impact on the subsequent performance.

Then, they proceed to the filling and sealing process (some factories may add a coating process before filling to protect the aluminum-plastic film with an additional protective layer to prevent electrolyte corrosion). At this point, the battery cells only retain the opening in the gas bag area, which is the filling channel. After the filling is completed, the edge of the gas bag needs to be pre-sealed (i.e., "one more seal"), using the same heat sealing principle as the top and side sealing, to melt and bond the PP layer of the aluminum-plastic film, achieving complete isolation between the internal environment of the battery cell and the external environment. At this point, the main packaging process of the soft-pack battery cell is basically completed, and the subsequent steps such as formation and capacity measurement will be carried out.

After the formation is completed, the battery cells will enter the second sealing process. This process consists of two steps: first, the gas inside the battery cells is extracted (some companies will list this as a separate Degassing process); then, the battery cells are resealed to ensure the sealing performance of the battery. In addition, some companies will add the airbag cutting and edge folding processes after the second sealing. For large-capacity and high-gas-production batteries, some enterprises will adopt a special process of pre-degas, formation, pre-degas, and second sealing.

During the second sealing process, the gas bag is first punctured by the cutting blade and then evacuated. This allows the gas inside the bag and a small amount of electrolyte to be extracted. Immediately after that, the sealing head is sealed in the sealing area to ensure the airtightness of the battery cell. Finally, the gas bag of the sealed battery cell is cut off, and after the gas bag is cut, trimming and folding are performed to ensure that the width of the battery cell does not exceed the limit. In this way, a soft-pack battery cell is basically formed.

Acey Intelligent's business covers pouch cell assembly equipment, battery cell&pack testing systems, prismatic, pouch battery pack semi-automatic&full automatic assembly machines, etc. If you have any need, please feel free to contact us at any time.