What Are You Looking For?

High tensile strength and no miscellaneous ball, this furnace much more energy saving than the furnace use common fiber materials.

Brand :

ACEYItem No. :

ACEY-MF8-14Customization :

OEM&ODM AvailableOrder(MOQ) :

1 SetCompliance :

CE CertifiedPayment :

T/T, L/C, PayPal, West Union, Alibaba Trade Assurance, EtcWarranty :

One Year Warranty With Lifetime SupportProduct Origin :

ChinaPackage :

Internal: Anti-Collision Protectio, External: Plywood CaseShipment :

By Air, Sea, Express, etc.

Product Description

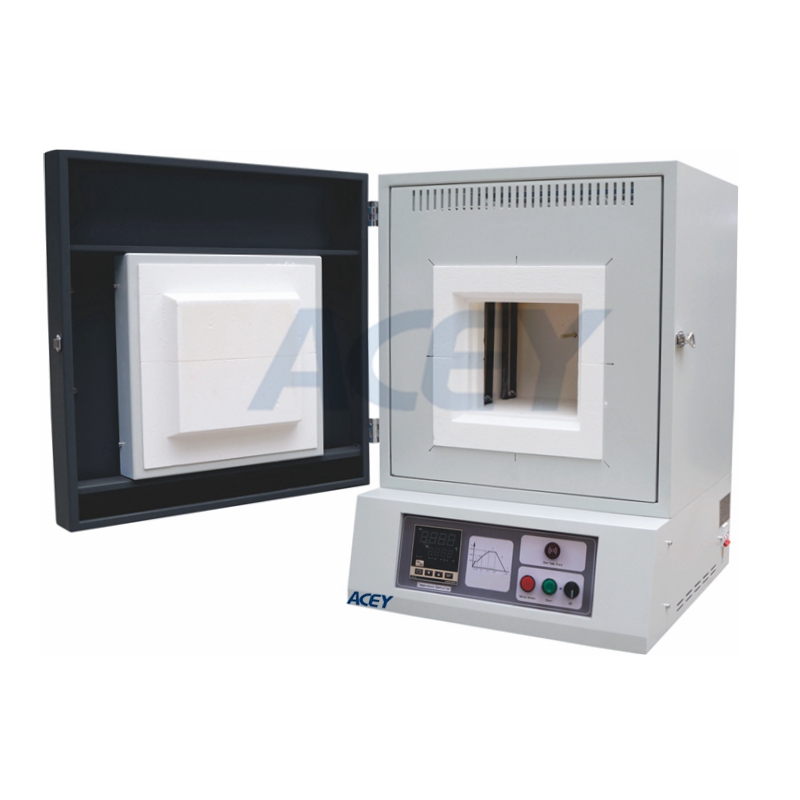

ACEY-MF8-14 muffle furnace is suitable for elemental analysis, measurement, small-sized steel hardening, annealing, tempering, heat treatment and heating in laboratory, industrial and mining enterprises, scientific research units, it can also be used for sintering of metal, stone, ceramic, dissolution analysis, gold melting of high-temperature heating etc.

Technical Parameters

|

Product Name |

1400C Laboratory Muffle Furnace |

|

Model No. |

ACEY-MF8-14 |

|

Type |

Box-type; Front-loading |

|

Furnace Structure |

1. The furnace is made of carbon steel with powder coating on surface, consists insulation material and heating elements and temperature control system, electric components and thermocouple 2. The furnace body and temperature controller were designed separately |

|

Inner Chamber Size |

W200xD200xH200 mm Chamber Capacity: 8 liters |

|

Designed max. Temp. |

1400°C |

|

Constant Working Temp. |

1300°C |

|

Min. Working Temp. |

Ambient |

|

Heating Rate |

Fast heat-up time due to the low thermal mass construction Suggest 10~15℃/min for longer life using of furnace |

|

Temp. Homogeneity |

Adopt the way of measuring temperature at 9-point; Temperature homogeneity is +/-5 degree |

|

Power Supply |

AC220V/5KW 50Hz, single phase |

|

Chamber Material |

1. Adopt high quality 1500 grade alumina polycrystalline fiber, which used Japanese technology (vac-sorb forming alumina polycrystalline fiber) with good insulation and durability properties, high tensile strength and no miscellaneous ball, this furnace much more energy saving than the furnace use common fiber materials 2. One-piece chamber and ecological insulation provide high thermal efficiency |

|

Heating Element |

1. High quality U shape Silicon Carbide rods 2. Vertical layout, distributes in two sides evenly, give an improved temperature gradient 3. Resistance of a SiC rods heating element does not change under normal use, and you can mix new and old elements together. |

|

Thermocouple |

Type S Installation location: back wall center |

|

Temperature Controller |

1. Top brand Shimaden PID with 32 programmable segments 2. Simultaneous LED display of actual temperature VS set point 3. PID automatic control and auto-tune function 4. temperature accuracy +/- 1 ºC |

|

Electronic Component |

SCHNEIDER maker air switch, solid-state relay, A.C contactor etc. |

|

Furnace Shell |

1. High quality cold-rolled steel sheets CNC processing, dual wall housing 2. Environmental electrostatic plastic powder coating on surface after deoiling, derusting, phosphating etc. 3. Energy efficient insulation keeps exterior safe to touch |

|

Furnace Door |

Manual type, Door opens sideways |

|

Safety Precautions |

1. Overheating & Broken thermocouple protection 2. Leakage circuit breaker 3. Automatic power off when furnace door opens 4. Over-temperature protection and alarm allow for operation without attendant(s) 5. Microprocessor-based PID control with self-tuning capability to prevent overshooting of set temperature |

|

Certification |

CE |

|

Warranty |

One year limited manufacturer's warranty (Consumable parts such as thermocouple heating elements are not covered by the warranty, please order replacements at related products respectively |

|

Warnings |

1.Toxic or explosive gasses are not recommended for use with this furnace without necessary safety controls and supervision. Please put furnace into fume hood for better safety. 2.Small cracks may appear on the surface of the refractory ceramics over extended use. Please place the sample in to a crucible. Never place sample on the chamber bottom directly. |

Product Display

Tags :